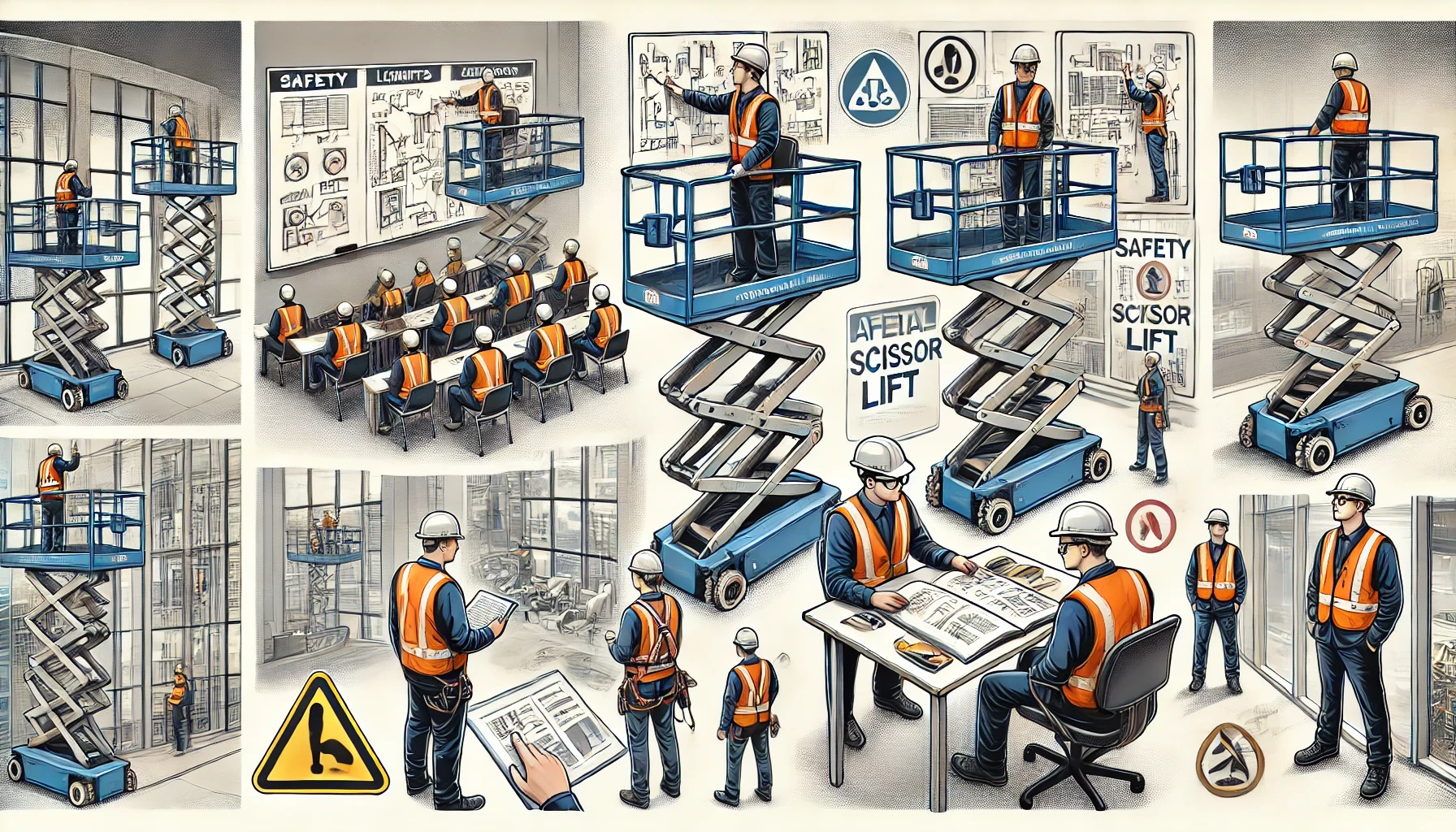

Aerial and scissor lifts are essential tools in construction, maintenance, and warehouse operations. However, operating them without proper training can lead to accidents, injuries, or even fatalities. That’s why Aerial & Scissor Lift Training is critical for ensuring workplace safety and compliance with OSHA regulations.

At Get Drivers Ed, we provide comprehensive lift training to help workers gain the skills needed to operate aerial and scissor lifts safely and efficiently. In this blog, we’ll explore the five key do’s and don’ts every operator should know to avoid workplace hazards and maximize efficiency.

1. Do: Complete Proper Aerial & Scissor Lift Training

Why Training is Essential

Before operating any aerial or scissor lift, it’s crucial to undergo proper training. OSHA mandates that all workers receive formal instruction before using this equipment to prevent workplace accidents.

What You’ll Learn in Training

At Get Drivers Ed, our Aerial & Scissor Lift Training covers:

Understanding lift controls and operations.

Safe maneuvering techniques.

Fall protection and safety measures.

Inspection and maintenance procedures.

Proper training ensures that operators know the risks and can navigate challenging work environments safely.

2. Don’t: Operate a Lift Without a Pre-Use Inspection

Why Inspections Are Necessary

A pre-use inspection is one of the most overlooked safety steps when using an aerial or scissor lift. Failure to inspect equipment can result in mechanical failures, injuries, or costly damages.

Key Areas to Inspect

Before each shift, operators should inspect the lift for:

✔ Hydraulic leaks or fluid levels.

✔ Damaged or missing guardrails.

✔ Faulty brakes or control systems.

✔ Worn-out tires or loose components.

A quick inspection can prevent accidents and ensure the lift is in proper working condition before use.

3. Do: Use Fall Protection Equipment Properly

The Importance of Fall Protection

Falls from aerial and scissor lifts are among the leading causes of workplace injuries. Using the right fall protection equipment reduces the risk of accidents and helps operators stay compliant with OSHA safety standards.

Best Practices for Fall Protection

✔ Wear a harness when required – Especially when operating a boom lift.

✔ Secure the lanyard properly to the designated anchor point.

✔ Never remove guardrails from a scissor lift.

✔ Avoid climbing or leaning over railings while working at heights.

At Get Drivers Ed, our training emphasizes proper fall protection procedures to reduce workplace risks and ensure compliance.

4. Don’t: Overload the Lift or Ignore Weight Limits

Understanding Load Capacity

Every aerial and scissor lift has a maximum weight capacity, which includes:

Operators and tools.

Materials being lifted.

Exceeding weight limits can cause equipment tipping, instability, or mechanical failures.

Tips to Avoid Overloading

✔ Check the manufacturer’s load rating before use.

✔ Evenly distribute weight on the platform.

✔ Avoid stacking heavy materials above guardrails.

✔ Ensure multiple operators don’t exceed the weight limit.

Ignoring weight restrictions can compromise safety and damage the equipment, leading to unnecessary downtime and repair costs.

5. Do: Maintain Awareness of Surroundings at All Times

Avoiding Workplace Hazards

Operating aerial and scissor lifts requires constant situational awareness to prevent collisions, tip-overs, or electrocution hazards.

Safety Tips for Awareness

✔ Keep a safe distance from overhead power lines.

✔ Use spotters in congested work areas.

✔ Be aware of unstable surfaces and uneven terrain.

✔ Stay alert to nearby workers and machinery.

At Get Drivers Ed, we train operators to identify potential hazards, ensuring that every lift operation is executed safely and efficiently.

Conclusion: Stay Safe with Proper Aerial & Scissor Lift Training

Using aerial and scissor lifts comes with inherent risks, but following the right safety practices can prevent accidents and injuries.

✔ Complete proper training before operating a lift.

✔ Always conduct pre-use inspections to check for safety issues.

✔ Use fall protection equipment correctly to reduce fall hazards.

✔ Follow weight limits to avoid tipping or damaging the lift.

✔ Maintain situational awareness to prevent collisions and workplace accidents.

At Get Drivers Ed, we offer comprehensive Aerial & Scissor Lift Training to help operators work safely, efficiently, and in compliance with OSHA regulations.

Take the first step in workplace safety—enroll in Get Drivers Ed today!